Products Introduction

Place of Origin:China

Type:Ceramic Raw Materials

Application:Industrial Ceramic

Material:Alumina Ceramic

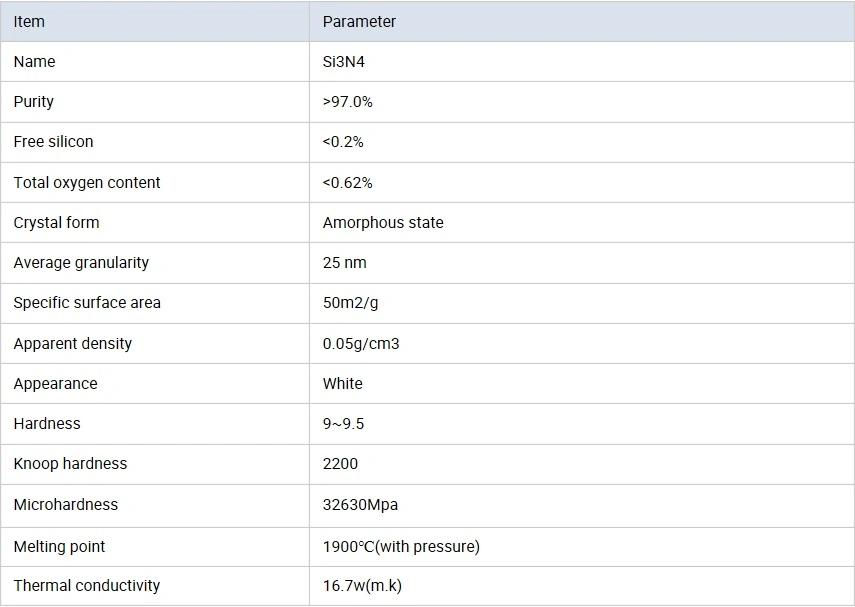

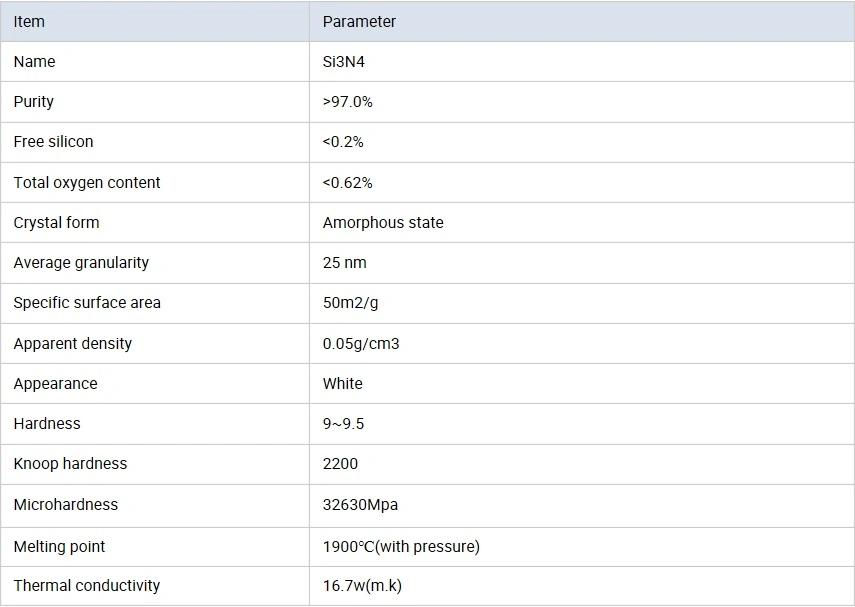

Model Number:Si3N4

Brand Name:Yuanxchen

Hardness:9~9.5

Knoop hardness:2200

Microhardness:32630Mpa

Melting point:1900ºC(with pressure)

Thermal conductivity:16.7w(m.k)

Elasticity modulus:2840-46060Mpa

Flexure strength:147MPa

Compression strength:490Mpa(reactive sintering)

Packaging Details

nano silicon nitride powder is available of 100g/bag, 500g/bag, 1kg/bag, according to customer's requirements.

Your Questions

Q1. What is your terms of payment?

A: T/T will usually be accepted,details could be negotiated.

Q2. What is your terms of delivery?

A: FOB, CFR, CIF, DDU,EXW

Q3. How about your delivery time?

A: Generally, it will take 10to 20 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q4. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings.

Q5. What is your sample policy?

A: we could offer the sample for free charge but do not pay the cost of freight.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them.

Generally, It will take 10 to 20 days after receiving your advanced payment. The specific delivery time depends on your items and quantity of your order.

Place of Origin:China

Type:Ceramic Raw Materials

Application:Industrial Ceramic

Material:Alumina Ceramic

Model Number:Si3N4

Brand Name:Yuanxchen

Hardness:9~9.5

Knoop hardness:2200

Microhardness:32630Mpa

Melting point:1900ºC(with pressure)

Thermal conductivity:16.7w(m.k)

Elasticity modulus:2840-46060Mpa

Flexure strength:147MPa

Compression strength:490Mpa(reactive sintering)

Packaging Details

nano silicon nitride powder is available of 100g/bag, 500g/bag, 1kg/bag, according to customer's requirements.

Product Performance

1.High purity, small particle size distribution, high specific surface area

2.Insoluble in water,but Soluble in hydrofluoric acid

3.A very important structural ceramic material and superhard material

4.Have features of lubricity,abrasion resistance,strong corrosion resistance and high temperature oxidation resistance.

5.Can resist thermal shock.When heated in the air to more than 1000ºC,it will never rupture with cold snap and severely heating.

6.Silicon nitride ceramic devices have low ceramic temperatures,with good dimensional stability and high mechanical strength

2.Insoluble in water,but Soluble in hydrofluoric acid

3.A very important structural ceramic material and superhard material

4.Have features of lubricity,abrasion resistance,strong corrosion resistance and high temperature oxidation resistance.

5.Can resist thermal shock.When heated in the air to more than 1000ºC,it will never rupture with cold snap and severely heating.

6.Silicon nitride ceramic devices have low ceramic temperatures,with good dimensional stability and high mechanical strength

Applications

1.Manufacturing precision structural ceramic devices:widely used in area of Metallurgy, chemical, machinery, aviation, and energy industries etc,balls and rollers using rolling bearings,Sliding bearing sleeve valve as well as the structural components required for wear resistance, high temperature resistance and corrosion resistance

2.Surface treatment of metals and other materials:Such as molds, cutting tools, turbine blade turbine rotors and cylinder inner wall coatings.

3.Preparation of high performance composites:Such as metal, ceramic and graphite-based composites,Rubber, plastics, coatings, adhesives and other polymer matrix composites.

4.Application in high abrasion Resistance rubber;Add 1-3 parts of Si3N4 powder to the bellows pipe whose main adhesive material is EPDM.The durability test of the product can be improved to from 200,000 time to more than 1 million times,and the performance is improved by 5 times.

5.Application of wear-resistant composite plating on metal surface:Silicon nitride has high hardness and low sliding friction coefficient.Its mechanical properties are higher than other ceramic materials.Compared with metal materials, the room temperature strength of silicon nitride can be maintained above 800 °C.Even between 1200 and 1400, it will remain considerable strength. If used in harsh conditions, it is advisable to coat the surface with Si3N4 metal composite

6.Application of absorbing infrared textiles:Silicon-based nano powder is nylon, polyester enhance electrical conductivity.Nano-silicon nitride has the absorption rate of the infrared absorption band of the human body above 97%, which is the best absorption infrared ultra-fine textile additive..

7Application of polysilicon and single crystal demoulding agent:When polycrystalline silicon and monocrystalline silicon are smelted to cast ingots, the ceramic powder is used for demoulding between silicon melt and quartz crucible

8.Application in LED luminescent material:Nanometer Si3N4 phosphors belong to luminescent materials with individual luminescence centers (cerium Ce3 europium Eu2). The energy transition process belongs to f-d transition

9.Application of nano silicon nitride in other industrial fields:High performance wear resistant, high temperature resistant rubber seals and tires,in anti-corrosion refractory coatings, high temperature insulating electronic materials and inorganic ceramic lubricating oils.It can also be applied to structural ceramics and inorganic composite materials.

2.Surface treatment of metals and other materials:Such as molds, cutting tools, turbine blade turbine rotors and cylinder inner wall coatings.

3.Preparation of high performance composites:Such as metal, ceramic and graphite-based composites,Rubber, plastics, coatings, adhesives and other polymer matrix composites.

4.Application in high abrasion Resistance rubber;Add 1-3 parts of Si3N4 powder to the bellows pipe whose main adhesive material is EPDM.The durability test of the product can be improved to from 200,000 time to more than 1 million times,and the performance is improved by 5 times.

5.Application of wear-resistant composite plating on metal surface:Silicon nitride has high hardness and low sliding friction coefficient.Its mechanical properties are higher than other ceramic materials.Compared with metal materials, the room temperature strength of silicon nitride can be maintained above 800 °C.Even between 1200 and 1400, it will remain considerable strength. If used in harsh conditions, it is advisable to coat the surface with Si3N4 metal composite

6.Application of absorbing infrared textiles:Silicon-based nano powder is nylon, polyester enhance electrical conductivity.Nano-silicon nitride has the absorption rate of the infrared absorption band of the human body above 97%, which is the best absorption infrared ultra-fine textile additive..

7Application of polysilicon and single crystal demoulding agent:When polycrystalline silicon and monocrystalline silicon are smelted to cast ingots, the ceramic powder is used for demoulding between silicon melt and quartz crucible

8.Application in LED luminescent material:Nanometer Si3N4 phosphors belong to luminescent materials with individual luminescence centers (cerium Ce3 europium Eu2). The energy transition process belongs to f-d transition

9.Application of nano silicon nitride in other industrial fields:High performance wear resistant, high temperature resistant rubber seals and tires,in anti-corrosion refractory coatings, high temperature insulating electronic materials and inorganic ceramic lubricating oils.It can also be applied to structural ceramics and inorganic composite materials.

Your Questions

Q1. What is your terms of payment?

A: T/T will usually be accepted,details could be negotiated.

Q2. What is your terms of delivery?

A: FOB, CFR, CIF, DDU,EXW

Q3. How about your delivery time?

A: Generally, it will take 10to 20 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q4. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings.

Q5. What is your sample policy?

A: we could offer the sample for free charge but do not pay the cost of freight.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them.

Generally, It will take 10 to 20 days after receiving your advanced payment. The specific delivery time depends on your items and quantity of your order.