China Factory Manufacture Silicon Nitride Ceramic Ball Bearings for Hydrogen Rollerblade Wheels

Specification for Full Ceramic Ball Bearings 6000/6200/6300/6400

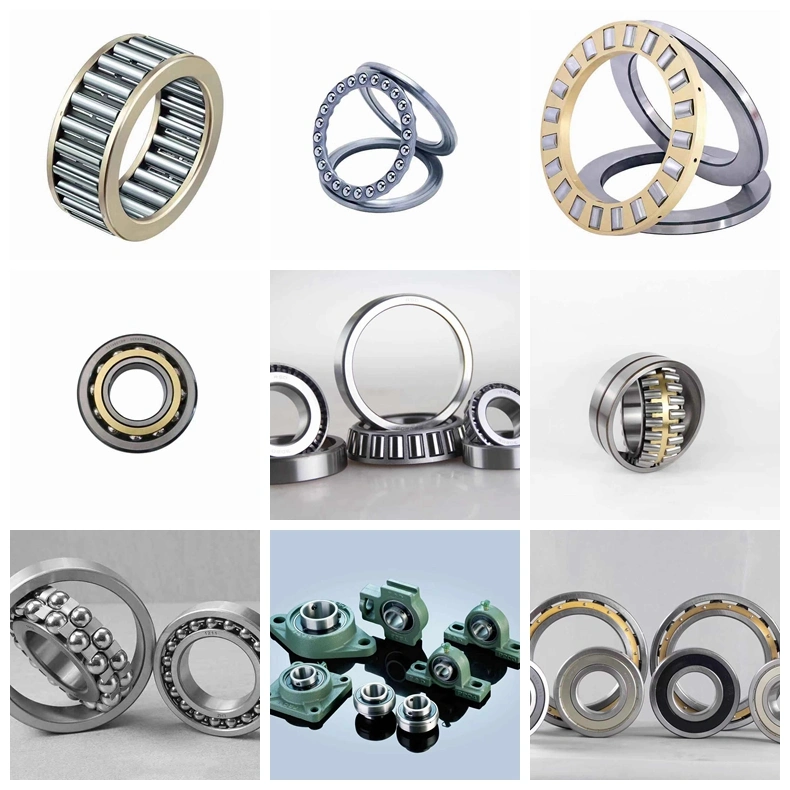

| Ceramic Ball Bearing Designations | ||||||||

| Deep Groove Ball Bearing | Self-aligning Ball Bearing | Thrust Ball Bearing | Insert Ball Bearing | Angular Contact Ball Bearing | ||||

| 6000CE | 6200CE | 6300CE | 1200CE | 51100CE | UC203CE | 7000CE | 7200CE | 7300CE |

| 6001CE | 6201CE | 6301CE | 1201CE | 51101CE | UC204CE | 7001CE | 7201CE | 7301CE |

| 6002CE | 6202CE | 6302CE | 1202CE | 51102CE | UC205CE | 7002CE | 7202CE | 7302CE |

| 6003CE | 6203CE | 6303CE | 1203CE | 51103CE | UC206CE | 7003CE | 7203CE | 7303CE |

| 6004CE | 6204CE | 6304CE | 1204CE | 51104CE | UC207CE | 7004CE | 7204CE | 7304CE |

| 6005CE | 6205CE | 6305CE | 1205CE | 51105CE | UC208CE | 7005CE | 7205CE | 7305CE |

| 6006CE | 6206CE | 6306CE | 1206CE | 51106CE | UC209CE | 7006CE | 7206CE | 7306CE |

| 6007CE | 6207CE | 6307CE | 1207CE | 51107CE | UC210CE | 7007CE | 7207CE | 7307CE |

| 6008CE | 6208CE | 6308CE | 1208CE | 51108CE | UC211CE | 7008CE | 7208CE | 7308CE |

| 6009CE | 6209CE | 6309CE | 1209CE | 51109CE | UC212CE | 7009CE | 7209CE | 7309CE |

| 6010CE | 6210CE | 6310CE | 2200CE | 51110CE | UC213CE | 7010CE | 7210CE | 7310CE |

| 6011CE | 6211CE | 6311CE | 2201CE | 51111CE | UC214CE | 7011CE | 7211CE | 7311CE |

| 6012CE | 6212CE | 6312CE | 2202CE | 51112CE | UC215CE | 7012CE | 7212CE | 7312CE |

| 6013CE | 6213CE | 6313CE | 2203CE | 51113CE | UC216CE | 7013CE | 7213CE | 7313CE |

| 6014CE | 6214CE | 6314CE | 2204CE | 51114CE | UC217CE | 7014CE | 7214CE | 7314CE |

| 6015CE | 6215CE | 6315CE | 2205CE | 51115CE | UC218CE | 7015CE | 7215CE | 7315CE |

| 6016CE | 6216CE | 6316CE | 2206CE | 51116CE | UC219CE | 7016CE | 7216CE | 7316CE |

| 6017CE | 6217CE | 6317CE | 2207CE | 51117CE | UC220CE | 7017CE | 7217CE | 7317CE |

| 6018CE | 6218CE | 6318CE | 2208CE | 51118CE | UC221CE | 7018CE | 7218CE | 7318CE |

| 6019CE | 6219CE | 6319CE | 2209CE | 51119CE | UC222CE | 7019CE | 7219CE | 7319CE |

| 6020CE | 6220CE | 6320CE | 2210CE | 51120CE | UC223CE | 7020CE | 7220CE | 7320CE |

| Applications:Food Processing Machinery, Electronics, Petroleum Industry, Medical,Skating board/shoes, Chemical Industry,Electronics,Auto/Automobile,Testing instrument,Metallurgical,Mining Machinery, Bike/bicycle/motorbicycle/electric bike.... | ||||||||

Ceramic Ball Bearings Introduction

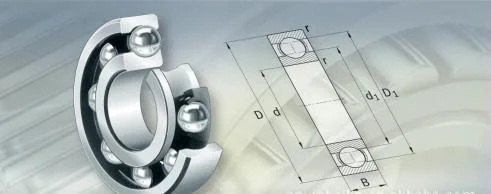

A ceramic ball bearing generally takes the form of normal ball bearings(normally deep groove ball bearings, self-aligning ball bearings, single row angular contact ball bearings, single direction thrust ball bearings), but made of ZrO2,Si3N4,Sic materials.According to different application situations, the ceramic ball bearings could be divided into full ceramic bearings and hybrid ceramic bearings, as the rings and ceramic ball retainers are made of other materials.

Benefits of Ceramic Ball Bearings

√ Reduced rolling resistance---mainly results from the ceramic balls' increased smoothness, dimensional stability, and increased uniformity over steel ball bearings. These properties ensure that applied loads are uniformly distributed over all rolling elements. Additionally, ceramic materials have a significantly lower coefficient of friction (~20-30 times less) than steel ball counterparts.

√ Reduced weight---Ceramic materials can weigh up to 40% less than comparable steel bearings. This reduced weight translates to decreased centrifugal loads exerted on the outer race as the bearing spins. This reduction of forces allows ceramic bearings to operate up to 20-40% faster than conventional steel bearings.

√ Increased durability---ceramic bearings can last anywhere between 5 and 20 times longer. The smoother surface of the ceramics also significantly reduces the risk of bearing seizure with little to no lubrication. Furthermore, ceramic bearings can operate in harsh environments due to their resistance to corrosion and degradation.

√ Some applications of ceramic ball bearings include: Ceramic Bearing Applications Medical equipment High-speed mills High-speed machining Precision instruments Pumps hydrogen roller blade wheels and compressors If you would like to learn more about our ceramic bearings, contact us for more information about our offerings, services, and capabilities.

Ceramic Deep Groove Ball Bearing Model 6203CE Picture Show

Guomai Bearing Factory Introduction

Shandong Guomai Bearing Co.,Ltd(hereinafter referred to as Guomai) was established in 1999, with more than 20 years of bearing research and manufacturing experience. The factory covers an area of 16000 m2,7000 m2 of which is manufacturing area and the other is office and warehouse. Guomai has large stock for normally used bearing models and this enables us to deliver the bearing to customers within the shortest time.

There are total 160 staffs, 6 automatic bearing assembly lines,116 CNC machines and 22 sets of precise inspection instruments. We not only have our own R&D team but also cooperate with Henan University of Science and Technology, Luoyang Bearing Research Institute to develop new bearing designing and manufacturing technology.

In addition to conventional bearings, Guomai also provides OEM and OM service to our respectable customers to meet their individual requirements.We introduced advanced milling, turning machines, heat treatment equipment and bearing testing machines to guarantee the quality of the bearings because we know "Quality is the life of Guomai" .Now our top products include taper roller bearing, angular contact ball bearing, deep groove bearing ,spherical bearing and cylindrical roller bearing with P5, P4 accuracy grade.

After so many years of developing, Guomai has built up an excellent sales network within China. Our two bearing brands "CVZ" and "Bentu" are well known and have high reputation within the industrial equipment and components field. Moreover, with confidence of our bearing quality, we started to export our bearings 4 years ago. Customers from Europe, North America, Middle East, Southeast Asia and Africa have enjoyed the happiness our bearings brought to them.

Guomai Bearing always upholds "WIN-WIN" spirit and believes in "Details determine success" philosophy, and keep improving bearing quality in the past 20 years. Some series of our bearings have similar quality with SKF, NSK, Timken, NACHI, KOYO, NTN and other world famous brands but with lower price.

Looking to the future, Guomai will insist on the technology innovation and processing levels to provide the most appropriate bearing products and service to our customers.

There are total 160 staffs, 6 automatic bearing assembly lines,116 CNC machines and 22 sets of precise inspection instruments. We not only have our own R&D team but also cooperate with Henan University of Science and Technology, Luoyang Bearing Research Institute to develop new bearing designing and manufacturing technology.

In addition to conventional bearings, Guomai also provides OEM and OM service to our respectable customers to meet their individual requirements.We introduced advanced milling, turning machines, heat treatment equipment and bearing testing machines to guarantee the quality of the bearings because we know "Quality is the life of Guomai" .Now our top products include taper roller bearing, angular contact ball bearing, deep groove bearing ,spherical bearing and cylindrical roller bearing with P5, P4 accuracy grade.

After so many years of developing, Guomai has built up an excellent sales network within China. Our two bearing brands "CVZ" and "Bentu" are well known and have high reputation within the industrial equipment and components field. Moreover, with confidence of our bearing quality, we started to export our bearings 4 years ago. Customers from Europe, North America, Middle East, Southeast Asia and Africa have enjoyed the happiness our bearings brought to them.

Guomai Bearing always upholds "WIN-WIN" spirit and believes in "Details determine success" philosophy, and keep improving bearing quality in the past 20 years. Some series of our bearings have similar quality with SKF, NSK, Timken, NACHI, KOYO, NTN and other world famous brands but with lower price.

Looking to the future, Guomai will insist on the technology innovation and processing levels to provide the most appropriate bearing products and service to our customers.

Workshop&Automatic Machines

Guomai Featured Bearings

Reasons to choose Guomai Bearings as your Ceramic Ball Bearings partner

1. Bearing designing: Guomai has our own bearing R&D team and adopts Germany technology. This enables us to provide OEM and ODM service to you.2. Production process: We strictly follow the 5S production process and acquired ISO9001:2008 quality management system certificate. Besides, we introduced from abroad world famous brands lathes and heat treatment equipment, this enables us to provide high precision bearings with similar quality to world famous brands such as SKF,TIMKEN,NSK,NTN,KOYO,NACHI and so on.

3. Materials: To ensure the high quality of bearings, we use high carbon chrome bearing steel which provides high rigidity, and high resistance to abrasive wear to produce the bearings. Low carbon cold rolled steel and low carbon stainless steel is also used according to customers' requirements.

4. Quality inspection: All bearings will be strictly tested before packing. We have Taylor talysurf, hardness meter,clearance detector,vibration(speed) measuring instrument,roundness instrument to guarantee all bearings are qualified with the standards.

5. Lubricants: Suitable lubricants are used to protect the bearings from oxidation or corrosion of parts thus enable our bearings with longer lifetime, low noise and better high temperature performance. Selection of lubricants is generally governed by the bearing application. Right choice of high quality lubricants could prevent metal to metal contact and conduct heat away from the bearings.

6. Packing: Guomai bearings pay attention to every detail in the bearing production process. We adopt plastic bag, Kraft paper, thick paper box and cartons to protect the bearings from unexpectable damage during the transportation and warehouse stock.

7. Factory direct marketing: We are the factory and not the distributor or trading agent, so we could provide the same quality with competitive price.

Exhibition

Bearing Packing and Delivery